One time I (Emily) built a table. I had no clue what I was doing, but I just knew I could figure it out. At the time, I was in a college sculpture class, so I had full access to a shop with all the right tools.

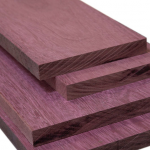

I didn’t know what I was doing, and I certainly didn’t have a planned out design in mind, I just decided to start hammering away, knowing it would come together perfectly. So, I riffled through the waste bin, picking out four 1 1/2 inch wide wooden rods that we roughly the same length. One rod was a bit longer, so I eyeballed it, and cut it to around the right size.

After that, I found a leftover piece of plywood that seemed about the right shape—it was three feet long (or so) and a couple feet wide. I thought to myself, “This will make the perfect table for my porch!”

With all of my “materials” accounted for, I got to work. I located some screws that seemed to be long enough, and I screwed through the top of the plywood into one of the rods. The rod pushed away from the plywood and left a gap between the table “leg” and the tabletop. Unfortunately, this being my first go at a woodworking project—I didn’t really understand what had gone wrong. I tried to fix the problem a couple of times, but I figured “that will be good, I’ll just do the other three like that and it will look like I meant for it to be that way.”

Of course, the other three legs did not all respond the same way, and I ended up cracking one of the legs somehow—so I had to dig around in the wood pile until I found something else that would work for the other leg. After so carefully installing the table legs, I pushed down on the table and it was very wobbly—but I thought, “that will just have to do”. I then decorated the table with some weird little aluminum discs I found in the scrap pile—I glued them on with wood glue and let them set for fifteen minutes or so.

After the table was “complete” I set it on top of my bike basket and secured it with a bungee cord and rode home. I proudly set it on the porch and said to my roommates, “ladies let’s have a beer on the porch to celebrate my new table!” We all sat around the table, and set our drinks on it and it worked fine as a table…well it worked fine as a table for a few days. Catastrophically, I went out to the porch one evening a few weeks later to find my table had collapsed from the weight of someone resting their feet on top of it. Oh well, little college table, rest in peace.

That being said, I learned through this process that I was in no way a craftsman and building a lasting beautiful piece takes a lot more than having materials and tools. Sure, I spent zero dollars and built this table from little scraps (this was the plus side), but it obviously lacked quality and care. The secret to good craftsmanship is a deep understanding of your materials and how they respond to you. Knowing how your tool will affect the wood or the metal—manipulating it to do just what you want it to in order to achieve the look you are after. The process for high-quality craftsmanship pairs know how with instinctive creativity.

Many people think like I thought when I built that table, we think, “oh, I can do that, and it will be a lot cheaper if I do it myself.” But when applied to other professions the theory doesn’t stand. For instance, would you do your own knee replacement surgery instead of hiring a professional because it would be cheaper to do it yourself? You could just mold a new knee out of modeling clay, cut your leg open, pull the old knee out and slap the knew knee in, sew it up and you’re good?

Brian always says, “People remember quality a lot longer than they remember price.” I have seen this truism played out over and over again, producing a quality product for people to enjoy for years to come. Support your local craftsman! Choose quality!